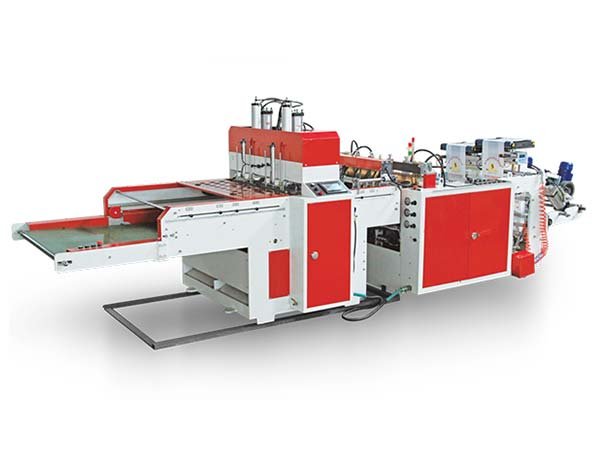

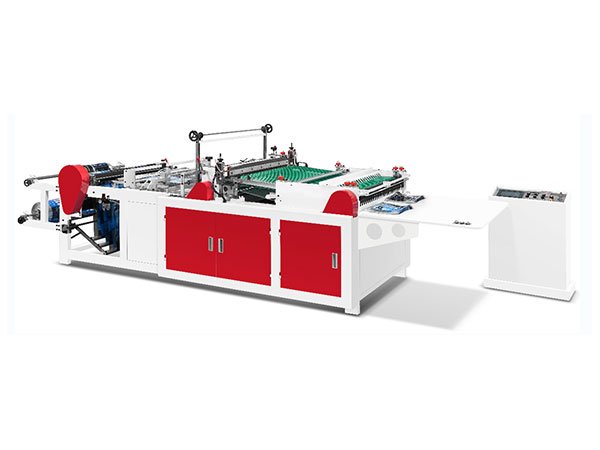

1. Whole machine controlled by central PLC control system with man-machine. More stable performance, easy for operation and maintenance. Chinese and English interface language can be shifted easily.

2. Constant auto-tension control for unwinding, EPC edge position controller, AC inverter constant speed auto material feeding.

3. Imported double servo-motor material dragging control system.

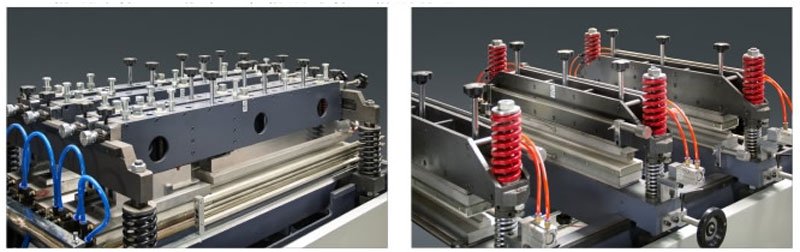

4. Main motor for up-down sealing and pressing equipped with inverter.

5. PID for sealing bar temperature adjustment, no touch auto control, centralized setting in man-machine interface.

6. Equipped with Pneumatic multi-function auto punching device, trim cutting and auto rewinding and static eliminator.

7. Temperature adjustment range: 0~300°C.

8. Counter: quantity, batch accumulation, preset available.

9. Operation Method: by length fixation control and/or by photocell tracking control.

10. Punching device: working rhythm can preset as continuous, interval or stop, punching time can be preset.

11. Material Skip Feeding: one to six times available.

12. Batch Conveying Function available, the quantity of batch can be preset.

| KDZD-A500 | KDZD-A600 | |

| Max.Diameter of roll material | 600mm | 600mm |

| Max.Width of roll material | 1050mm | 1250mm |

| Max.Capacity | 160 section/min(pieces/mm) | 160 section/min(pieces/mm) |

| Max.Mechanical speed | 40meter/min | 40 meter/min |

| Total Power | 40Kw | 40Kw |

| Weight | 4500kg | 5500kg |

| Outline Dimension | 9000x1900x1900mm | 9000x2000x1900mm |

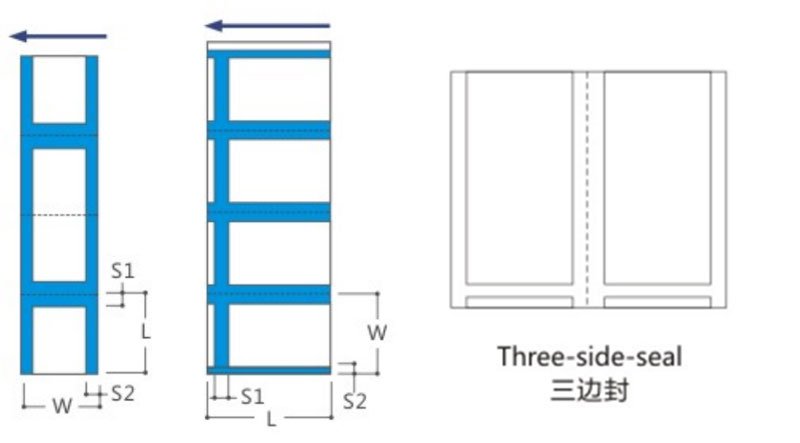

W:50-2400mm W:50-2400mm

L:75-600mm L:75-600mm

SI:5-30mm SI:5-80mm

S2:5-30mm S2:5-25mm

Remark: Skip feeding function available for length over 400mm.

Our Main parts cooperator as following brand,but standard parts all made from China.