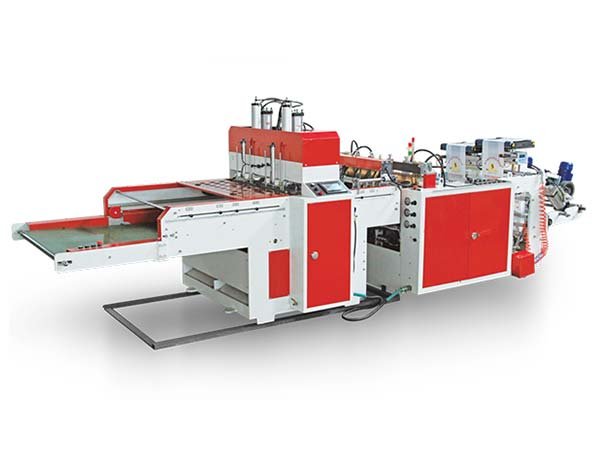

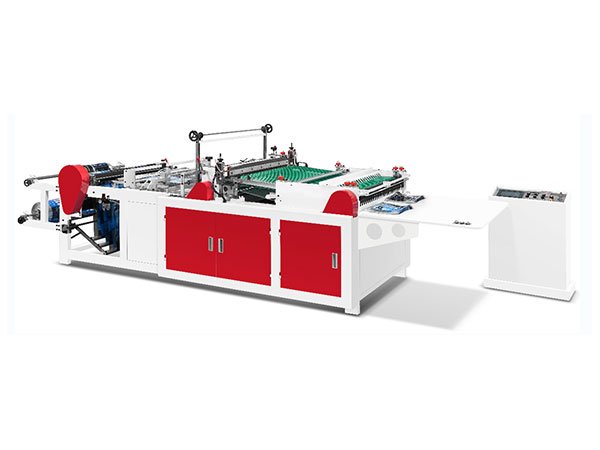

Properties and uses:

This machine is composed of drum feeding (pneumatic feeding, automatic deviation correction, tension adjustment), side gluing,printing paper electric eye tracking,

base paper into cylinder, fixed-length drawing cutting, bag bottom indentation opening, bag bottom gluing forming, bag out finishing and so on.

The whole machine is controlled centrally by PLC touch screen and servo motor controls the length of paper bag.

![]()

1) This is our new design food paper bag making machine, which used for KFC, Mcdonald's like chips, bakery and so on.

2)Automatic constant tension control for unwinding, Servo Motor system, motor for material feeding with inverter.

3)Main motor with inverter control

4)The machine can be stop automatically once out of material.

5)Wheel type gusset unit with motor driving.

6)Closed type automatic glue application and forming system.

7)Side lay working table, easy operation.

| MODEL | KDJD-400P |

| BAG LENGTH (L) | 120-420 MM |

| BAG WIDTH (W) | 80-240MM |

| INSERT PAPER EDGE (M) | 20-100mm (2M) |

| MACHINE SPEED | 50-400 PCS/MIN |

| MAX PAPER ROLL WIDTH | 260-720MM |

| PAPER WEIGHT | 40-80 G/M² |

| MACHINE POWER | 6 KW |

| OUTLINE DIMENSION | 4400X1700X1600 MM |